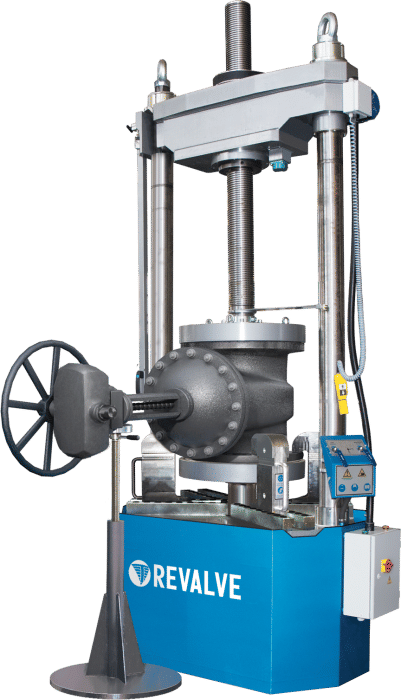

Verticle Test Bench

We take pride in having the largest vertical test bench in Thailand, which enables us to conduct comprehensive tests on valves. Our advanced capabilities also extend to online real-time testing, allowing us to monitor and evaluate valve performance in real-time and provide accurate and immediate results.

The purpose of the testing process is to evaluate the strength,

density, and overall quality of the body part materials. This is

achieved through a rigorous shell test, which measures the durability

and resistance of the materials used. Gate tightness tests are also

conducted in accordance with ANSI FCI 70.2 standards, focusing

specifically on classes II-VI. These tests ensure proper sealing and

optimal functioning of the gates. Environmental leakage tests,

including evaluations of gland seals, are performed to assess the

system's ability to contain and prevent leaks. Lastly, an operation

test is conducted to verify the smooth functioning and performance of

the tested components.

By conducting these tests, we can obtain a comprehensive assessment of

the materials' strength, density, gate tightness, environmental

integrity, and operational reliability.

Tested valves

- Control valves

- Shut off valves

Connection type

- Flanged (ASME B 16.5, GOST 33259)

- Welded ends (ASME B 16.25, GOST 16037)