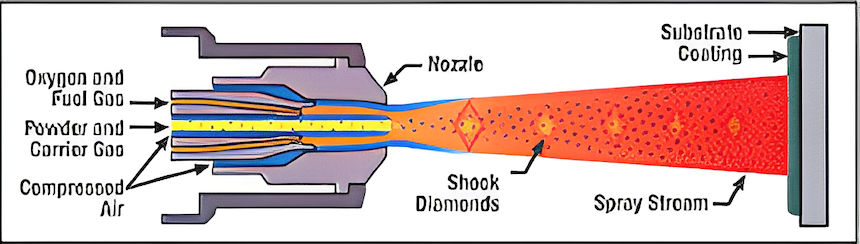

HVOF

The High Velocity Oxygen Fuel (HVOF)

spray process efficiently combusts oxygen and a gaseous or liquid

fuel to produce high kinetic energy while controlling the heat

input. In this process, the coating material, which is in powder

form, is introduced into the hot gas stream and uniformly heated

until it reaches a molten or semi-molten condition.

The

combination of high particle velocities, uniform heating, and low

dwell time results in coatings that are dense and tightly bonded to

the substrate. This process ensures more predictable coating

chemistries and creates coatings with fine, homogeneous

microstructures.

Photo Courtesy of Westaim Ambeon

Characteristics

Flame Temperature:

Approximately 5,000°F (2,760°C)

Fuel Gases:

Propylene or Propane or Hydrogen

Particle Speed:

Up to 4,500 ft/s (1,400 m/s)

.jpg?updatedAt=1709440865653)

.jpg?updatedAt=1709440868878)

.jpg?updatedAt=1709440865086)

.jpg?updatedAt=1709440863900)

.jpg?updatedAt=1709440865653)

.jpg?updatedAt=1709440868878)

.jpg?updatedAt=1709440865086)